From one-day demonstration experiments to long-term collaborative experiments, we will propose an experiment plan that meets your needs. Laser processing demonstration experiments allow you to explore what lasers can do.

[What is laser prcess, how does it work?]

Laser processing is always accompanied by various questions.

- What kind of laser processing can be done?

- What is the quality of laser processing?

- How much does laser equipment cost?

- How can I process it efficiently?

- What is the best laser?

- How to install a laser processing machine?

[The merit of our demonstration]

- Laser processing principle experiment

- Preparation for introduction of laser processing machine

- Development of new method

We will flexibly arrange demo experiments to realize the customer's desired processing. We can answer all your questions regarding laser processing. An application engineer will listen to your requests and set the optimal laser processing conditions.

- Processing jig preparation

- Laser parameter settings (average power, frequency, pulse width...)

- Processing experiments with varying parameters

- Utilization of optimal processing equipment

- Evaluation of processing results

- Investigation experiments towards the introduction of branched laser processing machines

■Usage hours

Weekdays (Monday to Friday) 10:00 to 17:00

■Usage conditions

- Pre-reservation Attendance

- Experiments and reports with samples received

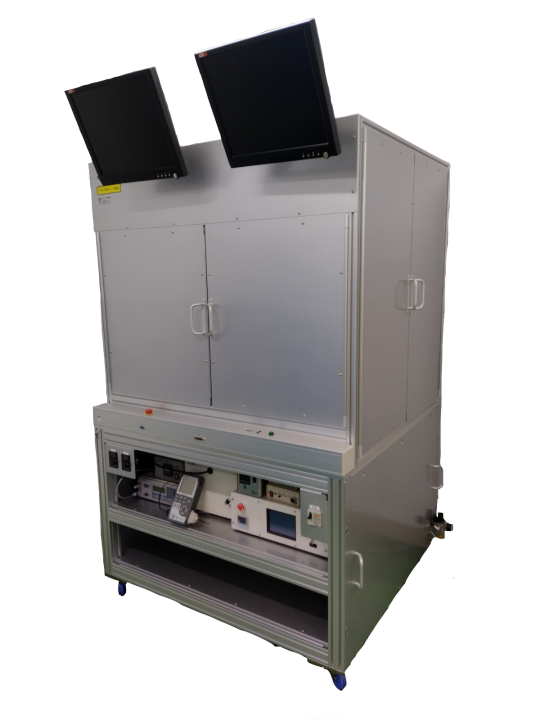

■Experiment compatible lasers

- Semiconductor laser (450nm, 800nm)

- Nanosecond laser (1064nm)

- QCW fiber laser (1064nm)

■Analysis and evaluation

Keyence high-resolution digital microscope, etc.